FWIW, I know of a guy who wrecked his jack from the heat.

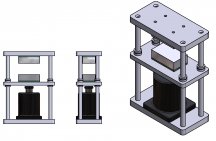

It was a standup Harbor Freight press that was used in the shop. He picked up some plates and only got like 3 squishes done before his jack wouldn't give pressure anymore. He said next time he would build the press with insulating washers.

I never saw the press, but only heard of his failure from a buddy after the fact.

It's a completely different setup than yours, so Idk if it relates. Heat does kill jacks tho.

I like that your putting quite a bit of forethought into this