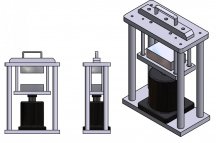

Northern tool 10 ton press w/gauge(very handy)-<$200 with coupon and free shipping.

Tupoke Rosin press kit with 3x5 plates, pid controller and heaters-$150

Rosin bags-shop around for the bags and micron sizes you want there's plenty.

All said I'm right under $400 and pressing away.

Greengenes has a plate build tutorial over on riu if you want to build your own plates,controllers and heaters with a parts list. He also has a YouTube video on it too,if it's still up.It's been a cple years.

Check it out,it'll help you and practically give you the info to diy your plates,pid controllers and heaters.

IMO,there are "cheap" are presses that get the job done with great results.There are also presses that get the job done with great results that have a lot of bells and whistles.

I'm a "as cheap as I can do it without sacrificing quality and still get the job done DIY'er".

Get a decent to good press(w a gauge preferably),some well machined plates caged or not.Your choice of plate material and good technique( I prefer bottle tec).

Plate size is a goo starting point.

Few questions-

How much material do you want to squish at one time? (I can get up to 20g of flower in my 2x4" bags comfortably.I squish no more than 10gs at a time now)

What type of material will you be inputing ...flower, trim,bubble hash etc.

3x3 & on up are the size plates that are common.

I have the 3x5 kit previously mentioned it came with thick heaters and a pid controller for both heaters.

You can source the controllers and heaters cheaper than I paid.

I might have saved $75-$125 had I diy'd my plates and sourced my own contollers and heaters.

Lastly,do not get a harbor freight press under the 20 ton.They eventually fail unless reinforced post purchase no sense in that.I bought 3 all failed and returned.

My 10 ton bench-top is perfect(for me) I haven't pressed beyond 1500 metric tons of pressure.

Good luck I'll be watching along.There will be more people with more experience and help soon.