Bc_ca

Super Active Member

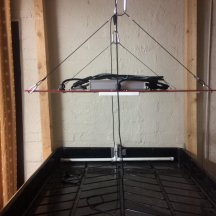

Just received my two hlg 550 v2 r.

It's a 1000w rated output replacement fixture. @ 1/2 the power demand great ... but there issues.

the reason I chose the the v r spec was to enable flexabity in transition from veg to grow.

If I get a strain the Vegs quickly then my veg space gets crowded not good. I can move the clones out and let them finish veg flip to flower in The 4x8 NFTable tray.

So 10 plants veg 3 weeks 20 " centers on the table. Those lights at 120 pull over 5 amps continuously x 2 fixtures that's 10 amps. That is a lot of current continuously for 70-90 day

Flat blade receptacle are prone to poor connection due to cable weight and accidental unplugs.

A continuous load (more than 3 hours) on a 20 amp protected service is only 16 amps.

There is the issue for those in grow room or grow tents larger than 4x8 .

As well, other stuff needs power too not just lights right and how many receptacles are in your room in your house sharing already other loads else where.

# 1 If your going to use a dedicated circuit for lights run a 30 amp breaker with #10 /3c bx/mc

Type cable use 220v the new 550 v2 r spec are auto voltage sensing. Now the fixtures will pull

No more than 3amps and you can expand out to a total of (3) 4x8 2 fixture grows on 1 circuit and still be at 18amps way below the continuous rating for a 30 amp branch protected circuit.

Now just from deciding on doing this properly for your current and future lighting needs you realize we can not use our existing house wiring for your grow needs !!!

Oh crap I need real power delivery that realization sets in.

Again we are 4x8 and bigger.

Grow veg lights,

Grow flower lights

Charcoal fan filter,

utility work lights ,

grow fans,

meters,

Water chiller,

pumps air and water,

CO2 delivery,

ac mini split ,

dehumidifier.

All of this needs power !

If we approach it like we did the lights you see we need a grower power station!

It's dedicated, it's clean. It's safe & mobile. It's built by you ! Lol .

That's my reality as I look to really build out into my 13x18 x9 grow room.

I'm going to have to build a grower power station (parts from home depo / lowes)

Pics and instructions and keep it simple.

It's a 1000w rated output replacement fixture. @ 1/2 the power demand great ... but there issues.

the reason I chose the the v r spec was to enable flexabity in transition from veg to grow.

If I get a strain the Vegs quickly then my veg space gets crowded not good. I can move the clones out and let them finish veg flip to flower in The 4x8 NFTable tray.

So 10 plants veg 3 weeks 20 " centers on the table. Those lights at 120 pull over 5 amps continuously x 2 fixtures that's 10 amps. That is a lot of current continuously for 70-90 day

Flat blade receptacle are prone to poor connection due to cable weight and accidental unplugs.

A continuous load (more than 3 hours) on a 20 amp protected service is only 16 amps.

There is the issue for those in grow room or grow tents larger than 4x8 .

As well, other stuff needs power too not just lights right and how many receptacles are in your room in your house sharing already other loads else where.

# 1 If your going to use a dedicated circuit for lights run a 30 amp breaker with #10 /3c bx/mc

Type cable use 220v the new 550 v2 r spec are auto voltage sensing. Now the fixtures will pull

No more than 3amps and you can expand out to a total of (3) 4x8 2 fixture grows on 1 circuit and still be at 18amps way below the continuous rating for a 30 amp branch protected circuit.

Now just from deciding on doing this properly for your current and future lighting needs you realize we can not use our existing house wiring for your grow needs !!!

Oh crap I need real power delivery that realization sets in.

Again we are 4x8 and bigger.

Grow veg lights,

Grow flower lights

Charcoal fan filter,

utility work lights ,

grow fans,

meters,

Water chiller,

pumps air and water,

CO2 delivery,

ac mini split ,

dehumidifier.

All of this needs power !

If we approach it like we did the lights you see we need a grower power station!

It's dedicated, it's clean. It's safe & mobile. It's built by you ! Lol .

That's my reality as I look to really build out into my 13x18 x9 grow room.

I'm going to have to build a grower power station (parts from home depo / lowes)

Pics and instructions and keep it simple.