WhyteWidow

Led Tech

What driver did you get? Didnt you get Eb series strips? Sry for delay I didnt even see your reply man.

What driver did you get? Didnt you get Eb series strips? Sry for delay I didnt even see your reply man.

He has a ceramic oven or whatever. To solder them. You cant do them one at a time. I mean I guess you could. But you have to get solder marks and circuits printed. Theres alot more to it than jus adding them and some solder. If you wanna make one. Just get on ebay. And check out like 3,4,5 diode stars. With leds already mounted. You jus need to solder wire to the board. And you can either get heatsink strips from ebay. Or mount them on just alum angle or channel. Or whatever.Thanks! How does a guy like me get ahold of that? I can solder, smt too.

700w in a 4x4 will rock. Thats 43.75w per sqft.I'm not in a hurry. I have plenty of CREE XP's and G3 and 660 reds. Adding about a 100 watts of 660's to the 6 QB's for a 4 x 4. I think an extra 100 watts of 660's would be enough for that space. Not sure how many microjoules/sec that will add. I haven't sat down and figured it up yet. The 6 boards are running right at 550 watts. So an extra 100 watts of reds and a small amount of G3's(cool whites) will get me right around 700 watts total or a little more should be enough. What do you think?

I have 24 vero 29's in a 4 x4 at the moment. I have to open the tent so some light can escape. lol700w in a 4x4 will rock. Thats 43.75w per sqft.

I have a few cobs. That I've run back when they first came on scene. I have veg light I built a ling time ago. Has 375w worth of cobs. Cxa3050s in 5k. Around a center two panel 175w Qb style center. It legit vegged the fuck outta some plants. But now it just sets in the closet. I have probably 7 or 8 lights in the closet, a few under our bed. And a few in the building where my grow is. That arent even being used now. LolI have 24 vero 29's in a 4 x4 at the moment. I have to open the tent so some light can escape. lol

I spread them out and turn them down to 6 or 700 mA and raise them up if need be. lol

I am COB poor!

And I use CO2 to help the plants use up some of that light.

I try and keep PAR around 8 or 900. Hard for me to figure efficacy when I am running so many at lower wattage. I am guessing at least 1.90microjoules/sec

All of my light bars are interchangeable 2ft and 3ft sections on 6" wide heatsinks (passive). I use them like an "Accordion". I have a partial prototype of mechanical hanging system I was building winter before last. It's for growing cannabis "trees" indoors . Fuck this sq/ft canopy BS. lolI have a few cobs. That I've run back when they first came on scene. I have veg light I built a ling time ago. Has 375w worth of cobs. Cxa3050s in 5k. Around a center two panel 175w Qb style center. It legit vegged the fuck outta some plants. But now it just sets in the closet. I have probably 7 or 8 lights in the closet, a few under our bed. And a few in the building where my grow is. That arent even being used now. Lol

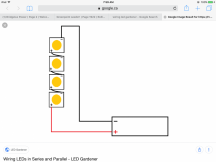

driver is hlg 320H C1400A. when i check LED gardener this is the wiring diagram they give. your cool bro dont worry bout itWhat driver did you get? Didnt you get Eb series strips? Sry for delay I didnt even see your reply man.

That diagram kinda looks to be parallel. With the 320h-c1400 you should be in series.driver is hlg 320H C1400A. when i check LED gardener this is the wiring diagram they give. your cool bro dont worry bout it

ok cheers dude. so should i wire it like you have yours? man i hate being an electronics noob lolThat diagram kinda looks to be parallel. With the 320h-c1400 you should be in series.

Yeah. Positive out from driver to + on first strip. Then other end of the strip - out to + on next strip. And again and again. Until your last strip, you come out negative to the negative of the driver. Jus a loop. Single wire from strip to strip.ok cheers dude. so should i wire it like you have yours? man i hate being an electronics noob lol

Makes sense. I could order stars and wire them up no problem. The real problem is I've developed a boner for your red strips and now I must have them.He has a ceramic oven or whatever. To solder them. You cant do them one at a time. I mean I guess you could. But you have to get solder marks and circuits printed. Theres alot more to it than jus adding them and some solder. If you wanna make one. Just get on ebay. And check out like 3,4,5 diode stars. With leds already mounted. You jus need to solder wire to the board. And you can either get heatsink strips from ebay. Or mount them on just alum angle or channel. Or whatever.

In series like you driver is a c1400. That means no matter what it puts out 1400mA. But the voltage is higher. So you got 10 strips. Max voltage on those strips according to the data sheet. Is 21.6vdc so you need a driver that puts out atleast 216vdc. The driver you picked does 114vdc to 229vdc. So your good. The actual output with a meter with the driver wide open. Will be 229vdc. Prob a little more bc meanwell under rates their drivers. Prob like 235-239v. So in series the strip gets the 21.6vdc @1400mA. In parallel your driver wouldve been HLG-320h-24A or B. No matter what you set the driver at. It will only have a output of 24vdc. But the 320h-24a pushes 13.34A wide open. So in parallel, you divide the number of strips or cobs or whatever you're using. So if you used the 24v driver it would 13.34÷10 strips. Which equals 1334mA to each strip at 24vdc. In parallel you use lower voltage across your circuit. 24v instead of in series you'll have 216vdc bc that's what the strip will pull at 1400mAThere are 2 ways to wire them. Series and parallel.

Parallel the voltage is the same for all.

Series the voltage adds.

So if you have 10 strips in paralel at say 20V then you need a 200V PS.

If you plan on running parallel then you need a 20v PS.

It's all up to the builder to deside which way to go there are pros and cons to each.

So it depends on what you PS is rated for and how many strips.

So if you are series you go + of you PS to plus of first strip.

The you go from its - to the + of the next in line.

So on until the end where the - is wired to your PS.

Like pick.

View attachment 475

cheers dudeYeah. Positive out from driver to + on first strip. Then other end of the strip - out to + on next strip. And again and again. Until your last strip, you come out negative to the negative of the driver. Jus a loop. Single wire from strip to strip.

so you think i should be using 18ga wire not 14?Usually 18ga wire is maximum for those push-in connectors on the strips. That could be your problem.

Yeah 18awg solid core wire. Lowes/home depot have thermostat wire you can get like 25 feet for like 10 bucks. Solid core is what needs to be used between strips.so you think i should be using 18ga wire not 14?